What is Digital Printing?

Digital printing is the process in which digital images are sent directly onto a variety of selected label materials on press. Unlike flexographic printing, there is no need for a printing plate during the print process; therefore, all colors and images are produced in one step. Instead, digital files like a PDF or Adobe Illustrator files are directly sent to the digital printing press to print on paper, synthetics, foils, cardstock, and many other substrates.

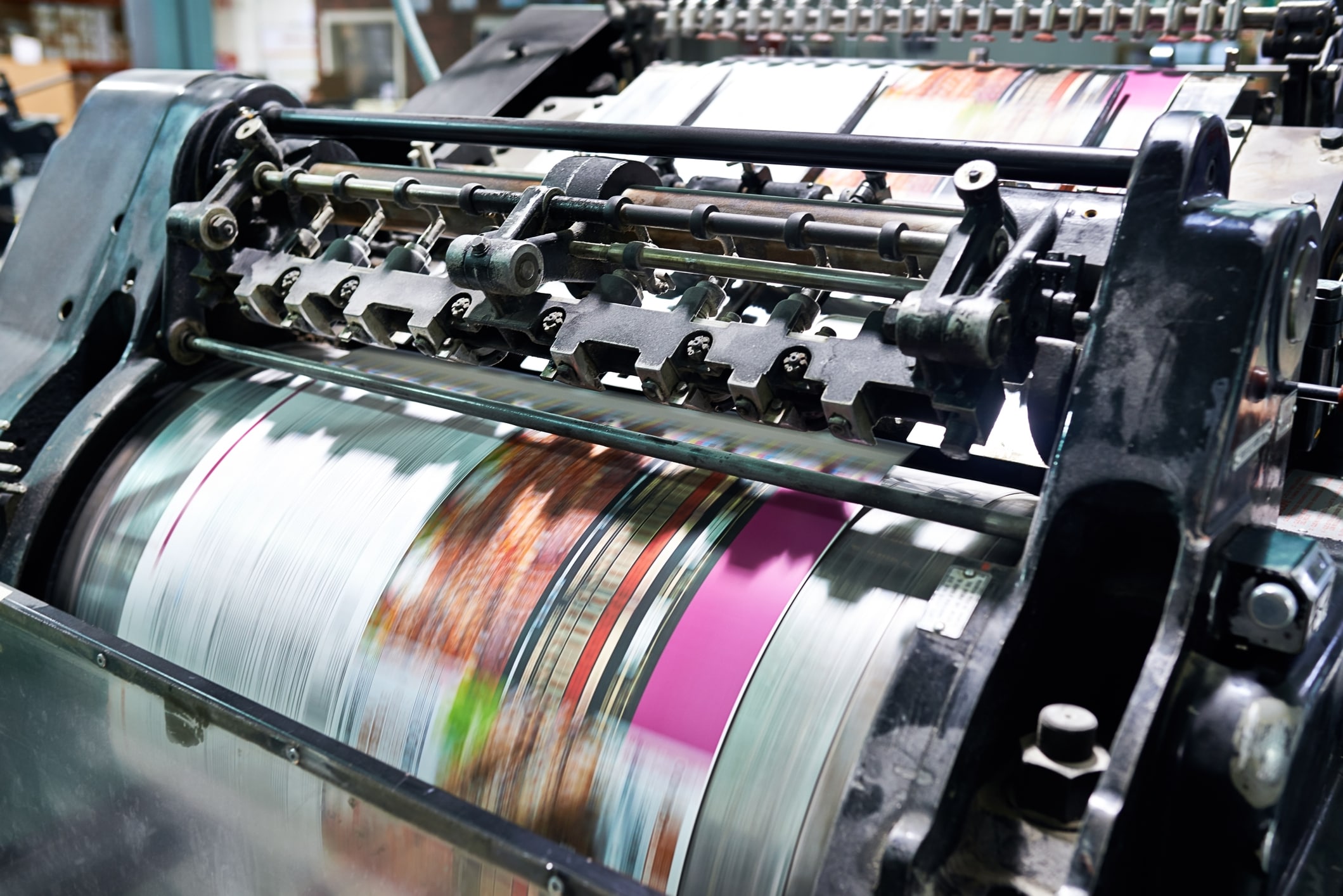

Digital Printing Vs. Flexographic Printing

As mentioned above, digital printing differs from flexographic printing because digital printing machines do not require the use of printing plates. Rather than using photopolymer plates during the print process, digital presses print an image directly onto the label material.

Common Uses of Digital Printing

Because of the differences involved in the digital print process, customers and printers alike will commonly turn to a digital press for certain needs or products. Read below for common examples.

- Prime Label Printing – If a job requires at least 4 colors, digital printing is a lot of the time, the best route to take. Likewise, if a label is being used to sell or speak for your brand, print quality is also a must. Color consistency, image quality, and vibrance of colors are all addressed during the digital printing process. Common examples of prime labels printing digitally are beverage labels (beer labels, distillery labels, etc.), food labels, and much more.

- Short Run Orders – Digital printing allows for a much lower minimum than flexo printing. If you are looking for colorful and unique labels to promote your brand or product, but are only looking for 500 – 5,000 labels, the digital printing process is perfect for you.

- Variable Print On Press – Elements such as text, graphics, and images may be changed from one piece to the next without stopping or slowing down the digital print process. Because flexographic printing requires plates for each unique image/color, variable printing is nearly impossible. Common variable labels printing digitally include flavor/name changes or a product, private labeling, UPC changes, and more.

Advantages of Digital Label Printing

- Label Cost – If your labels were to be printed on a flexographic press, you may be charged for a new label die – the die trims your label in the correct shape/size. As discussed above, a flexo press will also need plates – your 7 color label will need 7 plates. This can also become pricey. When you print your labels digitally, you will not be charged for these things; you’ll only be charged for your labels!

- Sustainable – The digital label printing process keeps waste minimal. Minimal set-up time means your costs stay low and you only pay for the labels you need – not material waste.

- Flexibility – Sometimes as your brand or product develops, you may want to make updates to your label, or create a new line of products. Even small changes during the flexo printing process can cost you. However, modifying artwork for a digital label is much easier and much more cost-effective. This is perfect if you have a family of products or SKUs that are using similar, yet unique labels.

Custom Digital Printing at Red Oak Label, LLC

Red Oak Label is the perfect partner for your business if you are looking for digitally printed prime labels! We are confident that we can compete with any price. Conveniently, your custom order will ship to you within 6 business days. Visit our website or call us at 262-780-9797. You can also email us at [email protected].