What is Flexographic Printing?

Flexography is a well-known printing method that uses rotary in-line features. Flexographic printing allows printers to print custom labels on flexible materials like paper, plastic, cellophane, metallic film, and more.

Flexography Uses

Flexographic printing, or flexo, became prevalent in the early 1900s. The original use of flexographic printing was almost entirely for food packaging. Today, about 60% of the packaging industry uses flexo labels.

-

Labels

-

Business Forms

-

Envelopes

-

Newspapers

-

Folding Cartons

-

Wallpaper

Advantages of Flexographic Printing

Every printing process has a unique set of features and advantages. Still, flexographic printing continues to be a leader in the industry. The main benefits of flexographic printing include:

-

Versatile - allows for many substrates and inks to be used, including water-based inks and solvent inks

-

Speed - Flexographic presses offer speeds over 950 feet per minute

-

Automation - Die-cutting, lamination, and sheeting can all be integrated up until the finishing stage.

-

Little Maintenance - this also helps reduce costs!

How Does Flexographic Printing Work?

Flexographic printing involves several key steps:

- Preparation: The process starts with creating a flexible printing plate, typically made from photopolymer material. The design is etched onto the plate using a laser or UV light.

- Mounting: The plates are mounted onto a rotating cylinder on the printing press.

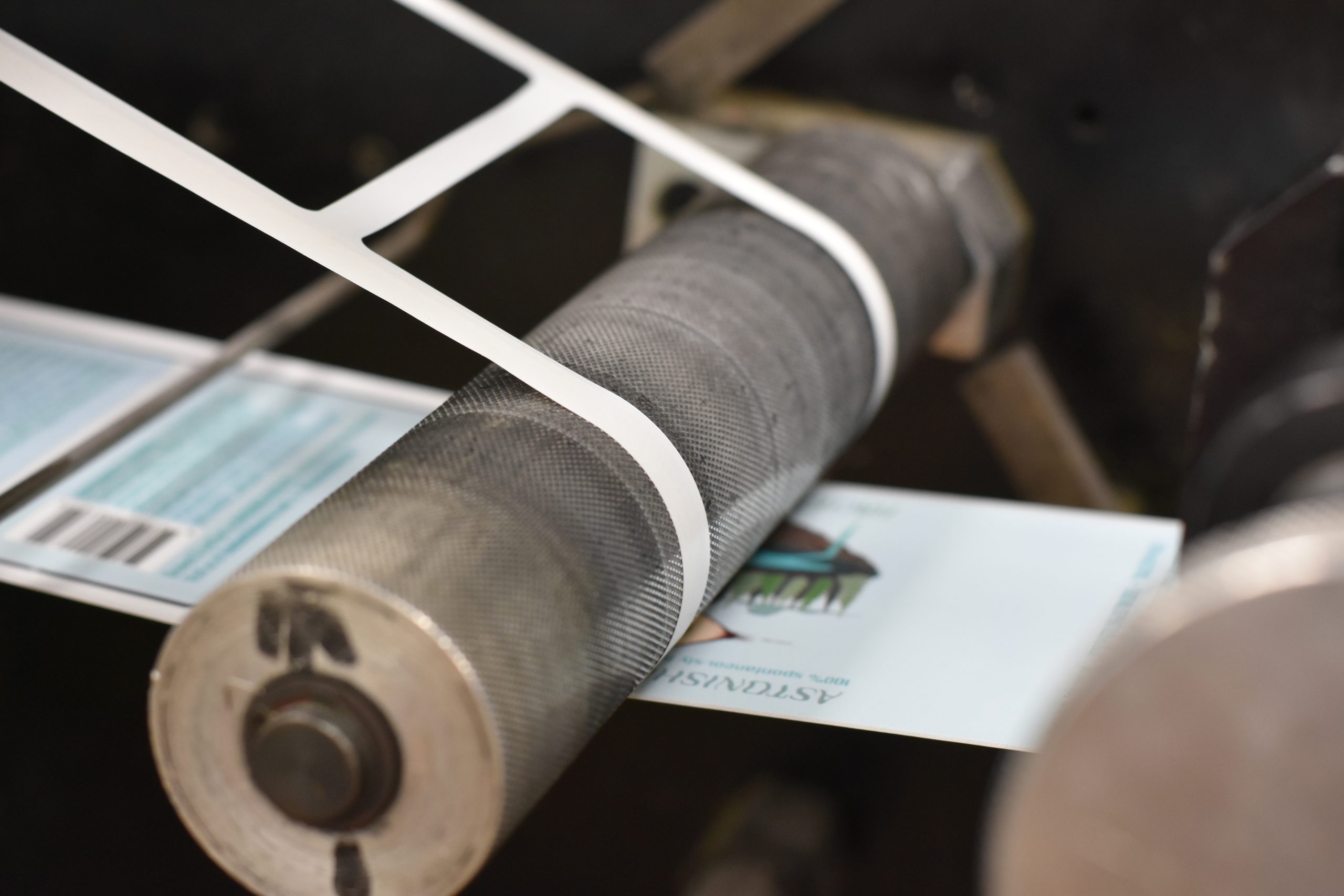

- Ink Application: Ink is transferred from an ink pan to an anilox roller, which is engraved with tiny cells that control the amount of ink transferred to the printing plate.

- Printing: The inked plate comes into contact with the substrate (material to be printed on), transferring the ink and creating the desired image. This process is repeated for each color in the design.

- Drying: After each color is applied, the substrate passes through a drying system, usually involving hot air or ultraviolet light, to set the ink.

- Finishing: Additional processes like die-cutting, embossing, lamination, coating, and sheeting are often integrated into the press to complete the printing job.

Flexo Printing FAQs

- What’s the difference between flexo printing and digital printing?

Flexographic printing uses flexible plates and rotary in-line systems to print on a variety of substrates, making it ideal for high-volume print runs with high-quality results. Digital printing, on the other hand, uses electronic files and prints directly onto the substrate without the need for plates. This makes digital printing more cost-effective for short runs and variable data printing.

- Can you color match when flexo printing?

Yes, color matching is achievable in flexographic printing. By using a combination of process colors (CMYK) and spot colors (PMS), printers can match specific brand colors and achieve consistent results across different runs. Advanced color management systems and spectrophotometers are often used to ensure precise color reproduction.

- How customizable are flexographic printing plates?

Flexographic printing plates are highly customizable. The design can be tailored to specific requirements, including various shapes and sizes. Plates can be created to accommodate different levels of detail and texture, allowing for a range of print effects. However, creating custom plates involves additional time and cost, particularly for complex designs.

Custom Flexographic Printing at Red Oak Label, LLC

Red Oak Label is the perfect partner for your business if you are looking for labels, films, foils, papers, and more! Your custom order will ship to you within 6 business days! Visit our website or call us at 262-780-9797. You can also email us at [email protected].